5 Tips for Designing a Tiled Shower

When designing a shower, several factors need to be considered. The space must be functional, safe, appropriate for the intended users, and enjoyable to use. However, the most critical aspect is ensuring it is designed to be watertight.

1. Waterproofing — Membrane or Tray

For membrane applications, the entire shower area is dressed with a sheet or liquid-applied waterproofing membrane and terminated at a drainage outlet, in accordance with AS 3740-2010 Clause 3.14.1 Figure 3.8. The membrane acts as the waterproofing element, with tiles installed over the top as a decorative finish and to protect the membrane system.

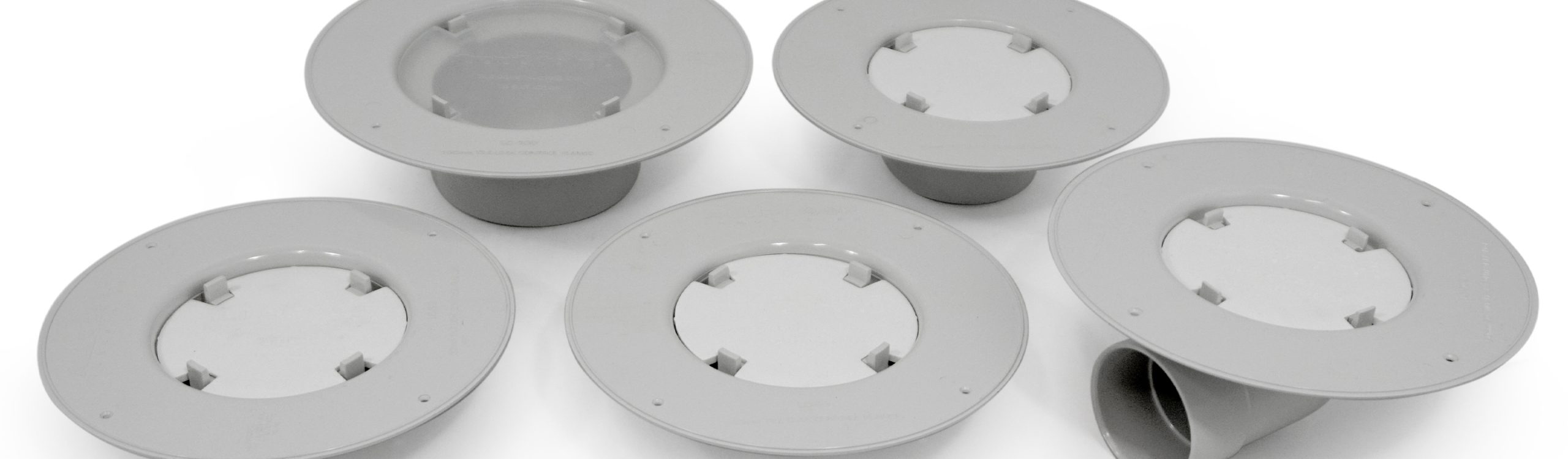

Allproof Industries manufactures a range of PVC Puddle Flanges compatible with leading waterproofing membranes. These flanges feature a textured surface ideal for membrane adhesion and include a PVC connection to the Drain Waste Vent (DWV) system incorporating a water trap or floor waste gully. Some sheet membranes require a clamped outlet, and for these applications, the Allproof Tilerite provides the ideal solution.

Allproof also manufactures custom-made Ttile-Over Shower Trays from stainless steel. These trays are made to measure the shower enclosure width and feature a threaded outlet welded to the base for DWV connection. Waterproofing membranes from the walls and surrounding bathroom area are dressed onto the tray. A shower tray offers the highest level of moisture management and assurance, making it ideal for upper floors or projects where leaks could impact multiple tenancies and revenue streams (such as apartments and hotels).

2. Level Entry or Hob

A level entry shower provides a seamless transition between the shower area and bathroom, helping to make the bathroom appear more spacious. Additionally, this improves accessibility by removing level changes that may pose a hazard to some occupants.

AS 3740-2010 Clause 3.4 requires a minimum fall of 1:100 for showers with a hob, screen, or step-down, and 1:80 for level entry showers. However, membrane suppliers often recommend greater falls (such as 1:50) to ensure surface water drains freely.

A level entry shower requires consideration of the flooring structure below. Installation typically involves cutting into joists to allow fall from the substrate downwards so the drainage outlet sits below the finished floor level. This may require engineering input, especially for laminated joists. In most cases, the shower area is trimmed out between timber joists to create a set-down with a screeded fall.

In contrast, a hob entry shower avoids structural modifications below the floor, as the fall is contained within the hob rather than cutting into the substrate.

3. Point Drain vs Channel Drain

Floor falls direct water to a drain positioned at the lowest point. A centrally located point drain requires falls from all directions, often resulting in cross-cuts in floor tiles. This is less desirable for large-format tiles. Using an Allproof linear Vision Shower Channel against a wall means the fall slopes in one direction, maintaining clean lines and full tiles on the shower floor.

For true level entry installations, channels should be placed against the wall opposite the entrance to avoid fall direction conflicts with level flooring at the threshold.

4. Recessed Shelves and Wall Niches

Recessed shower niches optimise space by eliminating shelves that protrude into the shower area. The Allproof Stainless-steel Niche is designed to provide durability and waterproofing integrity, addressing vulnerable corners and joints. Fixed to the timber wall structure, the waterproofing membrane is dressed onto the flange before tiles are applied.

Allproof niches can be customised, allowing wall-to-wall recessed shelving tailored to each shower design.

5. Finishes and Grate Selection

Allproof offers a variety of grate designs to complement different bathroom aesthetics while maintaining durability and high performance. Popular options include the Horizon shower channel grate and Elegance Plate, which feature brushed stainless-steel covers that hide the outlet while providing drainage around the edge. The architectural wedge wire grate offers a premium finish for tiled showers.

For a seamless look, the Invisi Drain or Tile Insert channel drain blends with surrounding tiles, leaving only a narrow drainage gap for a discreet yet efficient outlet that remains accessible for maintenance.

Allproof’s grate options are available in a variety of finishes to match other bathroom fixtures. Powder coating is also available in black, white, gunmetal, or any custom colour.

Engage Allproof for Your Next Project

Allproof offers an extensive product range and expertise for designing and constructing waterproof tiled showers. Engaging Allproof early in the design process ensures the desired aesthetic, functionality, and compliance with Australian standards are achieved.