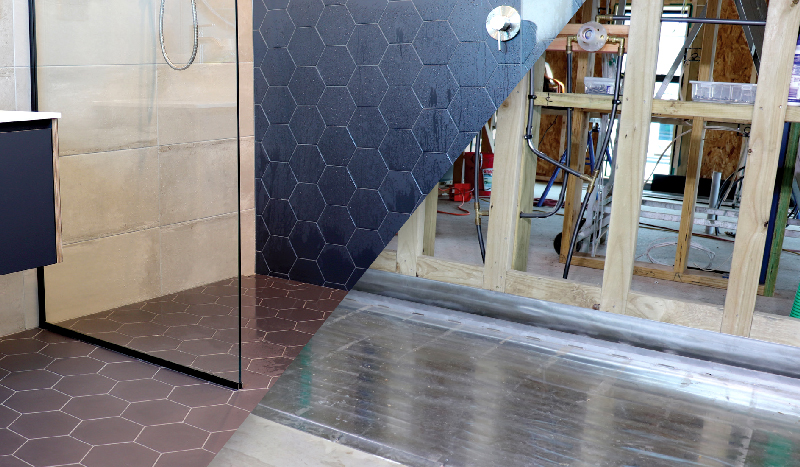

Urban intensification such as townhouses and apartments has been planned by authorities to relive pressure on the market and reduce city sprawl. With smaller dwellings involved in this strategy Allproof has noted a trend in the popularity of open concept bathrooms and the need to maximise bathroom space when it comes to these medium to high density projects which have tighter constraints on the building’s footprint. By removing a boxed shower unit a designer can dramatically open up space. A fully tiled shower provides a seamless wet area with minimal impact on the space available which is becoming more important as space comes at a premium.

A traditional tiled shower uses a waterproof membrane system bonded to a leak control flange creating a ‘tanked’ area. Tiles are then laid over the membrane with the appropriate fall towards a channel or point drain. This system is an excellent option and Allproof has built its reputation through a wide range of products and their integration with waterproof membrane systems. However, it has become apparent that there is demand in the market for a tiled waterproof system that provides the same level of assurance as a shower tray.

A stainless steel shower tray creates an impermeable barrier below the tiles that is highly resistant to any movement within the structure. This can become an important factor to consider when creating timber framed multi level dwellings with bathrooms above ground level or any development with intertenancy levels. One scenario that highlights this decision making process is Cordis Hotel in Auckland, even as a steel and concrete structure the designer decided the initial cost of putting tile over trays in each of the 235 bathrooms outweighed the cost associated with the risk of a failure. A leak in one bathroom would ultimately affect two or more rooms with the additional rooms being on the level below, this would greatly impact the revenue stream of the hotel along with the costs of repair.

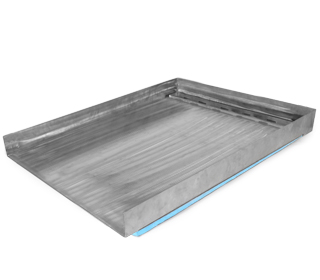

Specifying a tile over stainless shower tray also provides the assurance of performance and compliance with relevant AS/NZ Standards. A tile over stainless shower tray would be considered a “Preformed Shower Base” (AS 3740-2010; 3.6) needing to be sufficiently recessed into the wall and floor allowing waterproof membranes to be dressed onto the flange surface areas (textured to maximise bonding), it should also be supported to prevent distortion or cracking. Allproof have designed the tray to exceed the minimum fall outlined for ‘Type 1’ showers (AS 3740-2010; 3.13.5) by utilising an engineered base. The tile over stainless tray provides options of a 1:80 (recommended for hob entry) or 1:50 (recommended for level entry). The tray has a channel drain built into the system with tile bar options designed to suit varying tile depths and weepage holes allowing subsurface moisture trapped by the stainless tray to track into the waste outlet.

Allproof Stainless steel tile over trays have been developed so that they can be custom made specific to each project while reducing the work and impact on the installer. Each tiled shower tray caters to the unique variables of the project including overall size, shape, entrances/wall upstands, tile depths and grate options. The tray is supplied as a complete unit with the engineered base attached. The production process consists of completing an initial custom form with measurements, Allproof will then follow up with any questions and supply a shop/production drawing for sign off. By using a system with built in fall it removes the need for screeding on site, saving time and costs. The tray is fixed into place and tiles are directly applied following the install guide. The same process can be followed for stainless steel wall niches, a recent addition to the Allproof offering.