Five Key Considerations When Selecting Surface Water Drainage Systems

Effective water management in both residential and commercial construction projects depends heavily on selecting the right surface water drainage solution. From ensuring compliance with Australian Standards to choosing materials that align with environmental goals, surface drainage systems must be tailored to their specific application, surroundings, and long-term demands.

This article outlines five core considerations that architects, engineers, and specifiers should prioritise when selecting surface drains, drawing on Allproof’s advanced drainage technologies and proven performance across Australian projects.

1. Application and Installation Environment

The first factor to assess is the intended installation environment. Whether the project is a residential courtyard, a high-traffic commercial forecourt, or a landscaped podium deck, each requires a drainage system suited to both the topography and anticipated load.

For example, if the site’s surface drains to a centralised low point, a stormwater pit or sump system may offer the most effective capture. However, in areas with a consistent fall in one direction, a linear channel drain, such as Allproof’s Polymer Concrete (PC) Channel, is typically more efficient.

Additional elements like adjoining systems or architectural features also influence product selection. Where door or window joinery incorporates drainage under the sill, a traditional three-sided channel might obstruct water flow. In such cases, Allproof’s Perimeter Drain provides an elegant and unobtrusive solution, enabling seamless drainage while maintaining compliance with level threshold design.

2. Hydraulic Performance and Flow Capacity

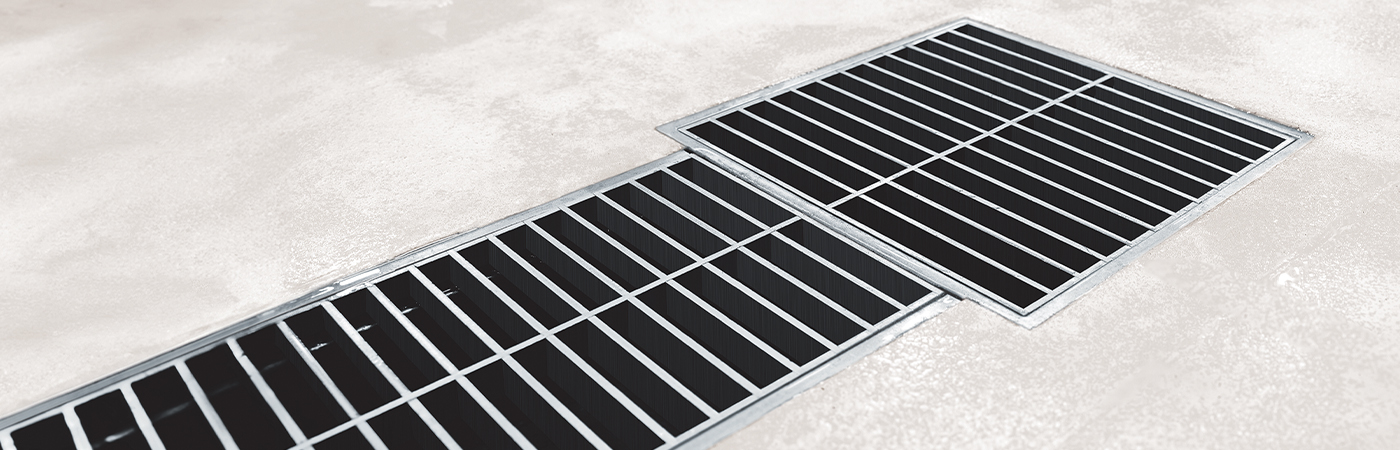

Hydraulics play a defining role in effective surface water drainage. It’s not just about size, it’s about performance under pressure. A steep driveway or sloped concrete apron may overwhelm narrow-profile slot drains, especially during periods of high rainfall. In these cases, a wider channel with a high-capacity grate, such as a cast iron cover on a sloped PC system, provides greater catchment and flow capacity.

Grate design also influences performance. While larger open areas allow greater flow, smaller apertures, though often required for safety, can be prone to blockage. It’s critical to match the drainage system to the hydraulic demands of the site while factoring in maintenance expectations.

3. Traffic Loads and Safety Compliance

The chosen drainage system must also stand up to the demands of pedestrian and vehicular traffic, which means selecting products rated under AS3996 Load Class standards.

For public walkways, parks, or urban spaces, slip resistance becomes essential. Grates used in pedestrian zones should meet AS4586 for slip resistance and feature heelproof designs with apertures less than 8mm, ensuring safety for all users.

Driveways, loading zones, and vehicle crossings demand higher load ratings. Allproof offers robust grates manufactured to suit these environments without sacrificing design appeal.

4. Environmental Durability

Australia’s diverse climates, from coastal zones to inland arid regions, demand drainage products that are both resilient and durable.

Material selection is crucial. In marine or coastal environments, 316-grade stainless steel is recommended for its corrosion resistance. For added protection, electropolishing is available, enhancing longevity and appearance.

Elsewhere, cast iron grates are often selected for their strength and natural weathering properties. As they oxidise, cast iron develops a stable patina that doesn’t compromise structural integrity. Alternatively, glass-filled nylon and polypropylene grates retain their clean black finish and offer corrosion resistance suitable for general applications.

5. Sustainability and Responsible Manufacturing

In today’s construction landscape, sustainability is no longer a secondary consideration; it is central to material selection.

Allproof leads the way in eco-conscious manufacturing by producing its plastic channels, pits, and fittings from 100% recycled polypropylene. These products not only meet performance and compliance standards but also contribute directly to the circular economy, reducing reliance on virgin plastics.

Further advancing their environmental credentials, Allproof’s main manufacturing facility is powered by solar energy, with more than 50% of its daily power needs supplied by renewable solar generation. This commitment ensures that the products you specify contribute to a greener built environment, without compromise.

The Right Surface Drain Makes All the Difference

Selecting the right surface drainage system is about more than just managing water, it’s about aligning performance, compliance, design, and sustainability with the long-term needs of the building. From material durability and hydraulic efficiency to safe, sustainable design, Allproof’s comprehensive product range is engineered to meet the complex demands of modern Australian construction.

For tailored advice or product specifications, consult directly with Allproof’s technical team or explore detailed listings online.