Full passive fire plumbing technical manual.

The Allproof Passive Fire Wraps are designed and tested on a wide range of plastic plumbing pipes through concrete walls/floors and plasterboard walls with a fire band. The passive fire wraps consist of one or more layers of intumescent material sealed in a polyethylene sleeve.

In the event of a fire, the intumescent material is activated and expands into the penetration cavity as the penetration service melts and deforms. When the intumescent seal expands, it forms a fire-resistant seal in the penetration, preventing the spread of fire.

The pipe wrap is designed to have the ends of the intumescent material meet around the circumference of the pipe. No overlap will exist, allowing the pipe to be centrally located within a core hole. For pipe sizes up to 100mm, only one layer of intumescent material is required, ensuring core holes can be kept to a minimum size. For plasterboard walls, a galvanized fire band is required to hold the fire wraps in place.

The Allproof Passive Fire Wraps have been tested at accredited fire laboratories in accordance with AS 1530.4 and AS 4072.1. The passive fire wraps have been tested and designed to be installed on the underside of flooring substrates for stack systems only. For plasterboard walls, the wraps need to be installed inside the walls using the fire band.

Subscribe for Product Updates

Subscribe for Product Updates

| wdt_ID | Code | Description | .pdf File | CAD File |

|---|---|---|---|---|

| 16 | FW32 | 32mm Fire Wrap | ||

| 17 | FW40 | 40mm Fire Wrap | ||

| 18 | FW50 | 50mm Fire Wrap | ||

| 19 | FW65 | 65mm Fire Wrap | ||

| 20 | FW80 | 80mm Fire Wrap | ||

| 21 | FW100 | 100mm Fire Wrap | ||

| 22 | FW150 | 150mm Fire Wrap |

Suitable for Fitting Within:

- Concrete, masonry and porous concrete wall constructions

- Concrete floor construction

- Plasterboard penetrations (with Fireband)

Features:

- Water resistant

- Advanced intumescent technology allows smaller

- core holes

- Simple to use – easy to install

- For use on various plastic pipes

- Removable “pipe wrap installed” label for pipe work/wall

Installation Instructions:

- Position fire wrap around circumference of pipe and remove backing from the self adhesive strip and join ends together.

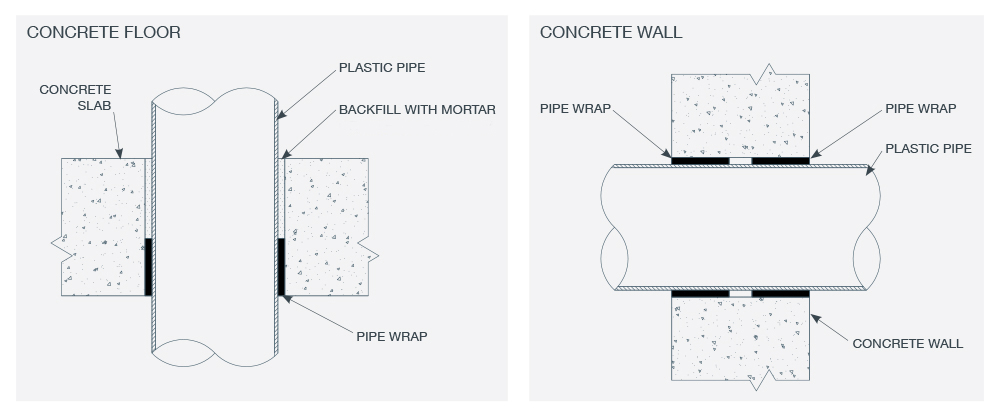

- Slide wrap into position ensuring wrap is located entirely within depth of the wall or floor. For floor applications, the wrap should be flush with the underside of the floor. For wall applications, two wraps are required – one from each side; each wrap should be flush with the outside wall.

- If there is a space between the concrete and the outer side of the wrap and above the wrap, backfill the space with mortar.

- The polyethylene sleeve can be removed and intumescent strip taped in place if the core hole is very tight.

- For plasterboard wall applications, an Allproof Fireband must be used.

Concrete Installation Details