What is a Puddle Flange? A Complete Guide

Puddle flanges, also known as leak control flanges, are a critical part of any waterproofing system. They ensure a secure connection between waterproofing membranes and drainage systems (DWV – Drain Waste Vent), preventing leaks and protecting surrounding structures from moisture damage. Compliance with Australian Standard AS 3740-2021 (Waterproofing of wet areas within residential buildings) and NCC Volume Two, E3 provisions is mandatory for all installations.

There are two main variations: those designed for tiled floors and those intended for vinyl floors. Each performs the same fundamental role but is adapted to interact with the different flooring systems.

How Waterproofing Membranes Work

Waterproof membranes form the primary barrier against moisture in wet areas such as showers, splash zones, or full wet rooms. Tiles, grout, and plank-style flooring are all porous to varying degrees; cracks, joins, or unsealed edges allow water to penetrate beneath the finished surface.

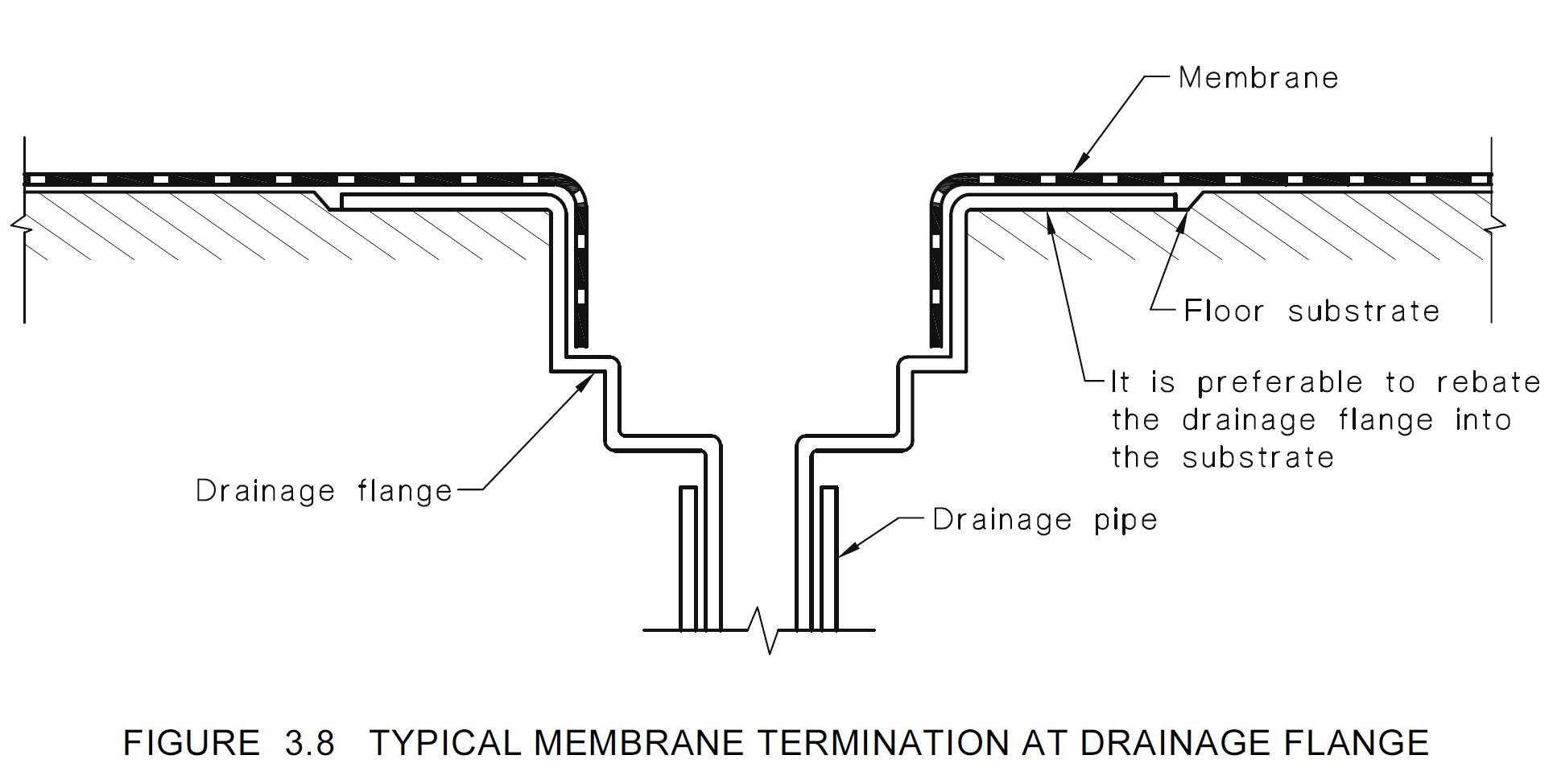

The membrane is the true protective layer, often visible as a coloured coating during installation, while tiles, silicone, and shower screens guide water toward the floor waste. Leak control flanges provide the crucial path for subsurface drainage.

Tiled Floor Puddle Flanges

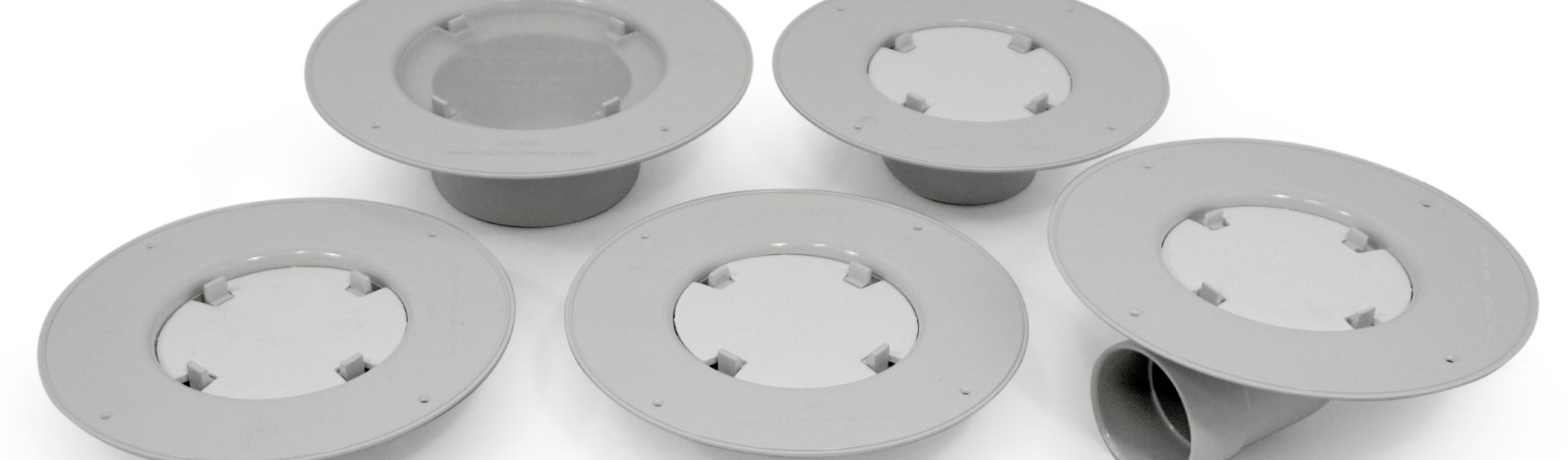

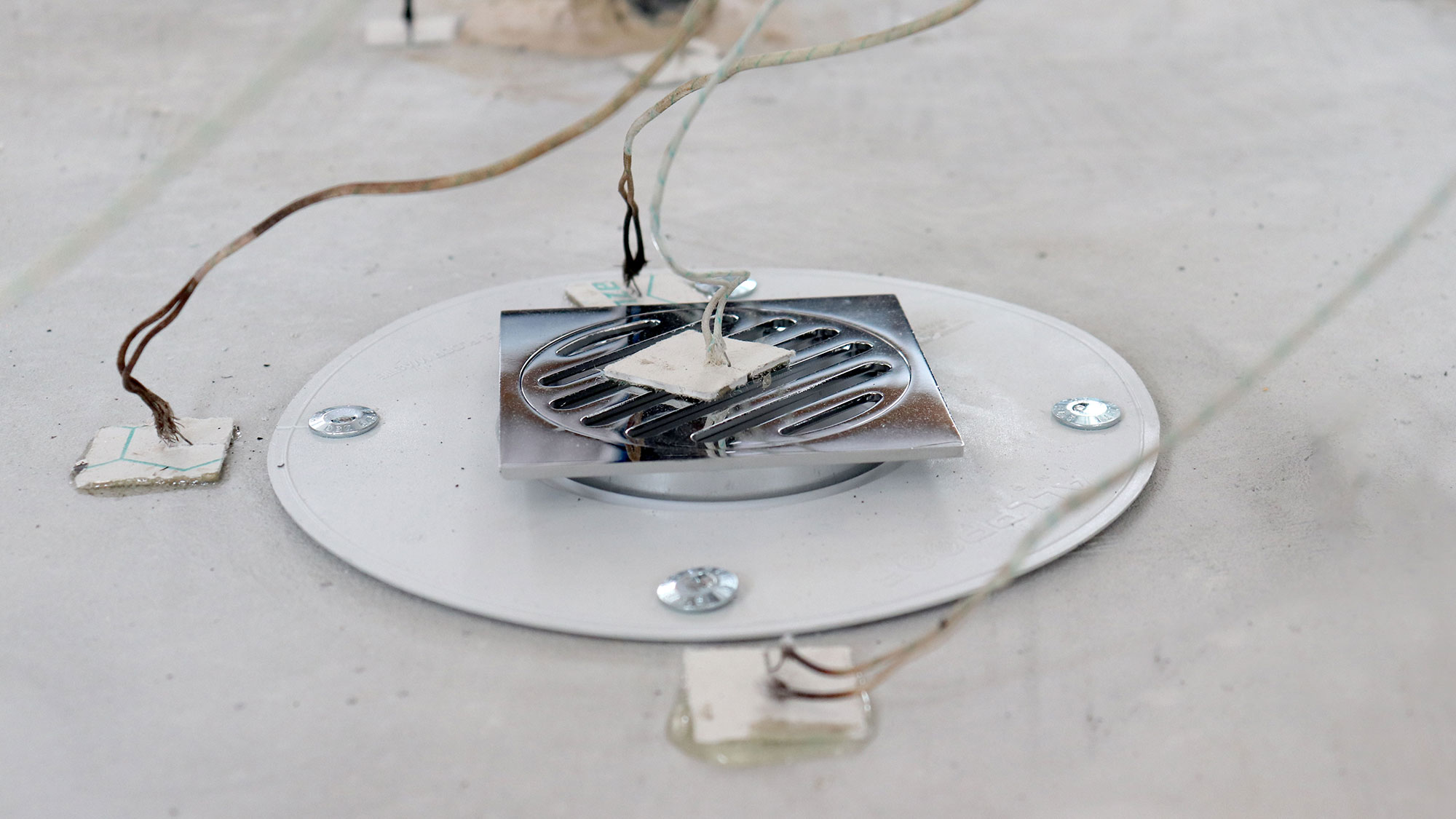

A tiled floor puddle flange is generally manufactured from PVC and is approximately the size of a dinner plate, providing a generous bonding area for waterproof membranes. Installed within a rebated section of the floor substrate, it creates a sealed, “tanked” area that directs water toward the central outlet, which connects directly to the plumbing system. Once tiling is complete, an adjustable spigot allows the grate to sit perfectly flush with the finished surface

Modern designs have improved installation efficiency.

- Tilerite Flange: purpose-designed for tiled floors, providing reliable membrane termination.

- Cyclone Leak Control Flange: features a threaded spigot for simple height adjustment and easier installation.

- Tilt-a-Grate: a passive fire-friendly design featuring an angled, height-adjustable spigot that ensures the grate finishes flush with surrounding tiles.

- Revolver: features and easy-clean removable gully bucket, low-profile design for confined spaces or restricted cavity depth, and rotating outlet for adjustable install (also suitable for vinyl floors).

For maintenance-friendly installations, Allproof Easy Clean Trap Floor Waste combines the Cyclone flange, Easy Clean Trap, and a low-profile floor waste adaptor. This provides a simple, hygienic solution, combining compliance with user-friendly cleaning access.

Many flanges require a bandage or bond-breaker strip to allow for movement between dissimilar materials, particularly where the membrane meets the flange. Properly installed weep holes or threaded spigots provide a controlled subsurface drainage path, ensuring moisture escapes into the floor waste without being trapped under tiles or screeds.

To complement the flange, a wide variety of grates are available. Stainless steel designs, such as Allproof’s Elegance, Wakatipu and Kaiteri series, combine durability with refined aesthetics, including the Invisidrain tile insert-style grates that conceal waste outlets for a discreet and sophisticated finish.

Linear Shower Channels

Linear shower drains are increasingly popular in modern bathrooms, offering clean lines and efficient water management. Installed against a wall or at the threshold, they require a single-direction floor fall, reducing tile cuts and installation time.

Allproof’s Vision Series uses a rectangular puddle flange for dual-barrier protection against surface and subsurface water, while the SC Series incorporates the flange directly into the stainless steel channel for a fully tanked, integrated solution. Both systems support removable grates, including tile insert and patterned options, allowing designers and installers to achieve a seamless and functional aesthetic.

Vinyl Floor Puddle Flanges

Vinyl flooring integrates waterproofing and the finished surface into one continuous layer. The puddle flange is rebated into the substrate, with the vinyl membrane dressed into the flange and secured by a clamping ring to create a watertight seal. A cam-lock grate completes the installation.

Australian solutions include:

- Revolver Vinyl Install: ideal for restricted cavity depth or maintenance access.

- Vinylrite: for general vinyl floor applications.

- Vinylrite HDPE: environmentally friendly option made from 100% recycled polypropylene.

These vinyl flanges are passive fire-friendly, designed to maintain compliance where required. While PVC flanges are commonly used, commercial settings often specify cast bronze for added durability and longevity. Grate finishes include chrome on brass, polished brass and stainless steel, allowing for both robust performance and an aesthetic match to the surrounding environment.

Installation Principles

Regardless of flooring type:

- Flanges must provide at least 50mm of continuous surface for the membrane to terminate.

- Screeds must be completed before flange installation to allow the membrane to bond correctly.

- Flanges should be flush with the finished floor; any proud flange can trap water and restrict subsurface drainage.

- Weep holes or threaded spigots must be incorporated to allow moisture to escape efficiently into the floor waste.

- Some systems may require bandage or bond-breaker strips to accommodate movement between the membrane and flange.

- Floor waste connections must allow subsurface drainage; glued or O-ring connections that block water movement are non-compliant.

- Passive fire protection requirements should be considered, especially for vinyl installations, and all components must be compatible.

Using systems aligned with Australian membrane and flooring suppliers ensures reliable, durable, and compliant installations.

The Importance of Puddle Flanges

Whether for tiled or vinyl floors, puddle flanges are fundamental to maintaining building integrity by preventing leaks and meeting mandatory compliance standards. Innovative systems, such as Allproof’s Leak Control Flange, Tilerite, Tilt-a-Grate, Cyclone, Revolver, Vinylrite, and Easy Clean Trap, ensure long-term reliability, straightforward maintenance and compatibility with a variety of grates, membrane systems, and passive fire protection solutions. Properly specified and installed puddle flanges protect your building and meet regulatory compliance requirements.