A puddle or leak control flange is a construction product that connects the waterproofing system to the plumbing drainage system, also known as DWV (Drain Waste Vent). This is required in all floor waste installs by the Australian standard AS 3740-2010. There are two types of puddle flanges designed to suit either tiled floors or vinyl floors, the design changes for each one depending on how it interacts and connects with the waterproof flooring system.

HOW TILED FLOOR WASTES ARE DESIGNED TO WORK

A tiled floor puddle flange is generally made from PVC plastic, is round, about the size of a dinner plate providing a large surface area for the bonding of the waterproof membrane to. It has a drainage hole and male pipe connection in the centre. The waterproof membrane is applied over the floor and walls prior to the tiles being installed. The tile drainage flange is rebated into the floor (substrate) so that the waterproof membrane is applied over the top creating a ‘tanked’ area allowing the flow of water towards the outlet in the centre of the puddle flange. The drainage system is connected to the male outlet connection on the underside of the flange. Once the tiles have been installed a spigot is used to adjust the height of the grate so it is flush with the finished floor level.

TYPES OF TILE DRAINAGE FLANGES

There are various designs for tile floor puddle flanges that provide features to aid installers. The Allproof Cyclone and Tilt a Grate flanges have adjustable spigots allowing for height and, in the case of the Tilt a Grate, angled adjustments. The traditional method is to cut the spigot to the desired height; it’s easy to understand why the Cyclone and Tilt a Grate can save installers a lot of time and hassle on site. Other design variations may include the Revolver, this is an easy clean drain system, the drainage flange include a gully trap in the form of a removable bucket. This system is ideal for scenarios where the floor/ceiling cavity below the grate restricts the depth of the drain and gully trap height.

TILE FLOOR GRATES

There are a wide selection of grates that have been designed to provide choice for bathroom and shower designs. Chrome on brass remains a popular selection for trades, however Allproof also offers a range of stainless grates for homeowners, interior designers and architects to select from for a more customised shower and bathroom. The elegance series provides 8 grate designs, manufactured from high grade stainless steel and fixed to an ASA moulded base creating a durable, easy maintenance and architecturally aesthetic design. Complimenting this range is the Wakatipu and Kaiteri series, these are similar to the elegnace plate design by using a lid without perforations, a drainage path between the body and grate allows for water to drain while giving the bathroom a sophisticated look. The lid hides the drain below meaning when a person is stood in the shower looking down at the drain the waste material and any grease is hidden from line of sight.

LINEAR SHOWER CHANNELS

Shower channels are quickly becoming a popular choice for modern bathrooms, they can be installed against a wall or used as a threshold drain preventing the flow of surface water from escaping the shower area. The fall (slope) in the floor only needs to be set in one direction, reducing angled cuts in tiles for a better aesthetic and less time (costs) for tilers to install. Allproof offers two designs for shower strip drains. The Vision Series requires a shallow trench to be created in the floor; a specially designed rectangular puddle flange (VF80) is then set into the trench, the entire area is waterproofed with the membrane dressed into the flange outlet. The stainless channel is installed over the top of the membrane with the outlet directed into the flange. This creates two barriers, the channel catches the surface water while the membrane catches any subsurface moisture. Tiles can be set up against the channel and sealed with a bead of silicone creating a tidy install, the grate is separate from the channel and removable for cleaning. Grate options include a tile insert channel, which blends the grate surface in with the surrounding floor tiles providing a discreet drainage path between the grate and channel walls.

The SC Series incorporates the flange into the stainless steel channel. The flange area spans out onto the floor and up walls, if set against any. The channel is rebated into the floor substrate and walls so that the flange is flush with the surfaces; the waterproof membrane is then dressed onto it, creating a tanked area. The channel has an outlet which the plumbing system is connected to. Tiles are then installed keeping a small gap from the grate so it can be removed for maintenance.

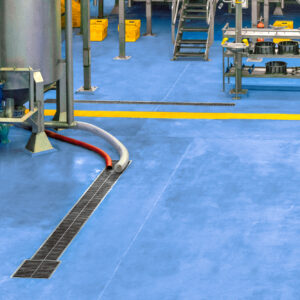

VINYL FLOOR PUDDLE FLANGE AND GRATES

Vinyl floor membranes provide a moisture barrier and a finished floor surface within the same material lining. A vinyl floor puddle flange is installed much the same way as the tile version by rebateing it into the floor substrate and connecting the DWV system. The vinyl membrane is glued to the floor and dressed into the drainage flange; a compatible clamp ring is then used to mechanically clamp the vinyl membrane into place. A cam lock grate is installed, creating a flush finish with the floor and a watertight surface with point drain. A Vinyl flange is often moulded from PVC, however a popular choice for commercial applications is a cast bronze flange, these provide extra durability and a longer life span. Grate finish options include chrome on brass, polished brass and stainless steel.