Why Specify a Tile Over Shower Tray?

Urban intensification strategies such as townhouse and apartment developments have been implemented by authorities to alleviate pressure on the housing market and reduce urban sprawl. These developments often feature smaller dwellings, which has led to a growing trend in open-concept bathrooms aimed at maximising space efficiency. This is especially relevant in medium to high-density projects, where the building footprint is limited. By removing traditional boxed shower units, designers can create a more open and spacious bathroom. A fully tiled shower provides a seamless wet area with minimal spatial impact, an increasingly valuable benefit as available space becomes more limited.

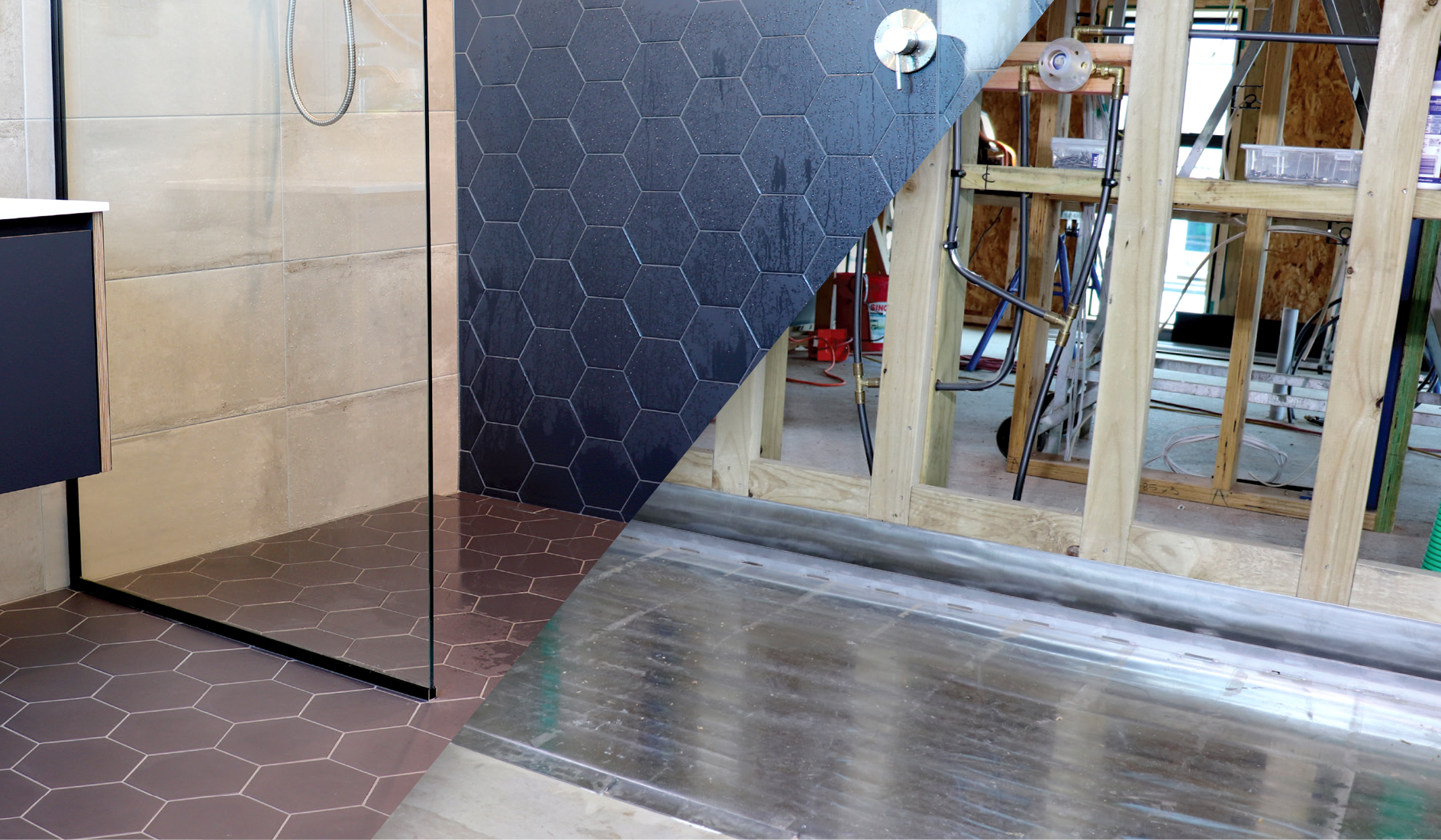

Traditional tiled showers utilise a waterproof membrane system bonded to a leak control flange to create a ‘tanked’ area. Tiles are laid over this membrane with an appropriate fall directed towards a channel or point drain. This approach is well-established and Allproof has built its reputation on providing products that integrate seamlessly with these waterproof membrane systems. However, there is a growing demand for a tiled waterproof system that offers the same level of reliability and assurance as a shower tray.

A stainless steel shower tray provides an impermeable barrier beneath the tiles, offering excellent resistance to movement within the building structure. This is particularly important in timber-framed, multi-level dwellings with bathrooms situated above ground level or in developments with inter-tenancy floors. For example, the Cordis Hotel in Auckland, despite its steel and concrete construction, opted to install tile-over trays in each of its 235 bathrooms. The decision was based on an assessment that the initial investment in these trays would be justified by the risk mitigation benefits. A leak in one bathroom could affect multiple rooms, including those below, significantly impacting the hotel’s revenue and incurring costly repairs.

A stainless steel shower tray provides an impermeable barrier beneath the tiles, offering excellent resistance to movement within the building structure. This is particularly important in timber-framed, multi-level dwellings with bathrooms situated above ground level or in developments with inter-tenancy floors. For example, the Cordis Hotel in Auckland, despite its steel and concrete construction, opted to install tile-over trays in each of its 235 bathrooms. The decision was based on an assessment that the initial investment in these trays would be justified by the risk mitigation benefits. A leak in one bathroom could affect multiple rooms, including those below, significantly impacting the hotel’s revenue and incurring costly repairs.

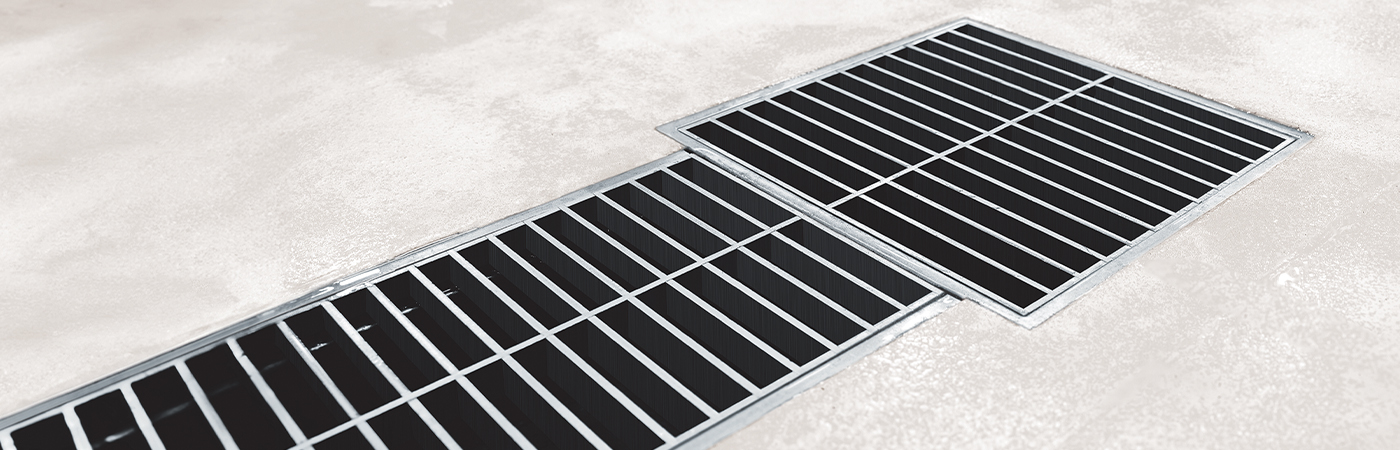

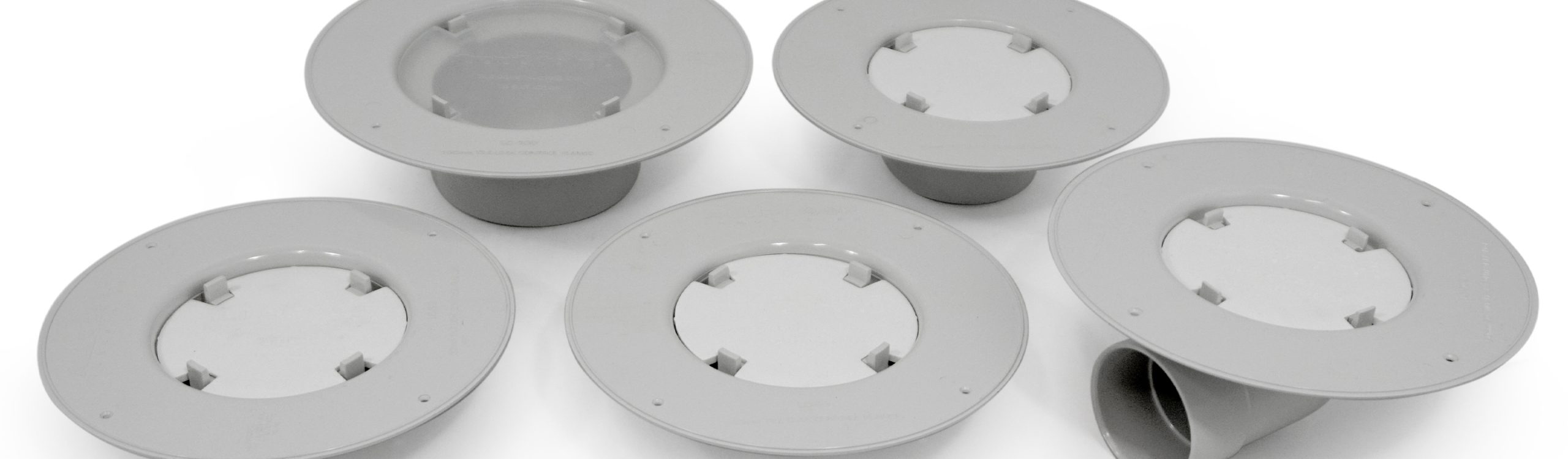

Specifying a tile-over stainless steel shower tray also ensures compliance with relevant Australian and New Zealand standards. Under AS 3740-2010, a tile-over stainless steel shower tray is classified as a “Preformed Shower Base” (section 3.6). It must be recessed sufficiently into the wall and floor so that waterproof membranes can be dressed onto the flange surfaces, which are textured to maximise bonding. The tray should be adequately supported to prevent distortion or cracking. Allproof designs its trays to exceed the minimum fall requirements for ‘Type 1’ showers (section 3.13.5 of AS 3740-2010) by utilising an engineered base. The tile-over stainless tray offers options with a 1:80 fall (recommended for hob entry) or 1:50 fall (recommended for level entry). The tray incorporates a channel drain system with tile bar options to accommodate various tile thicknesses, as well as weep holes to allow moisture trapped under the tray to drain into the waste outlet.

Allproof’s stainless steel tile-over trays are custom-made to suit the specific requirements of each project, reducing installation complexity and on-site work. Each tray is tailored for variables such as size, shape, entrances, wall upstands, tile depths, and grate options. The trays are supplied as complete units with an engineered base already attached. The production process begins with custom measurements submitted by the client, followed by a review and a shop drawing for approval before fabrication. Using a tray with a built-in fall eliminates the need for on-site screeding, saving both time and costs. The tray is fixed in place, and tiles are then directly applied following the installation guide. This streamlined process can also be applied to stainless steel wall niches, a recent addition to Allproof’s product range.