New Side Outlet Roof Drains for Compact Membrane Installations

Expanding the Range for Greater Design Flexibility

In response to evolving project requirements and tighter cavity spaces in modern construction, Allproof has expanded its range of PVC membrane-compatible roof drains with the introduction of new 88° outlet configurations in a variety of sizes. These new additions enhance installation flexibility and simplify design for membrane roof and balcony drainage systems, particularly where space constraints or complex angles are present.

A Heritage of Waterproofing Innovation

Allproof’s legacy in waterproofing and drainage solutions spans over more than 35 years. Originating in the 1980s as a supplier of waterproofing products, the company soon recognised the demand for specialist drainage solutions for membrane installations. By the early 1990s, Allproof had developed and launched a comprehensive range of roof and balcony drains, becoming a trusted name among architects, specifiers, and waterproofing professionals across Australasia.

Today, Allproof continues to manufacture and innovate from its base on Auckland’s North Shore, offering a complete system of membrane clamp ring drains, grates, and accessories. These are engineered to meet the rigorous demands of both adhesive and heat-applied membrane systems, providing performance, durability, and ease of installation across a wide range of applications.

Material Versatility and Proven Performance

Allproof’s membrane roof drains are available in a variety of materials tailored to different waterproofing methods:

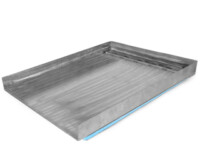

- Standard PVC bases for adhesive membrane installations

- Thick-gauge PVC and bronze bases for heat-applied membranes

The thick-gauge PVC range, in particular, has gained popularity due to its balance of durability, versatility, and cost-effectiveness. It also reflects Allproof’s commitment to sustainability, with these components manufactured using renewable solar energy.

The product lines include the VRTW (a compact, small-diameter base) and the Sureflow (a large-diameter option), both designed to suit varying project requirements and drainage capacities.

New 88° Side Outlet Product Launch

The latest update to the range includes:

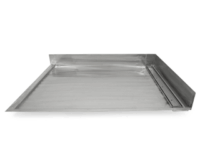

- Two new 88° VRTW bases with 65mm and 80mm outlet sizes

- A new 88° Sureflow base with a 100mm outlet

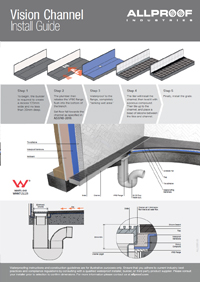

These integrated 88-degree outlet configurations eliminate the need for separate pipe bends to change direction, which can reduce overall installation depth by up to 100mm. This compact design is particularly advantageous in roof cavities, internal gutters, and balconies, where space is often limited.

By integrating the angled outlet directly into the drain body, specifiers and installers benefit from a more compact and streamlined solution. The resulting space savings can enable longer pipe runs within roof cavities, offering greater design freedom in locating downpipes and simplifying coordination with structural elements.

Installation Features and Material Options

Each drain body features solvent weld connections to ensure a secure and watertight fit to pipework. The PVC flange provides an excellent bonding surface for waterproof membranes, and is paired with a clamp ring to protect membrane edges and create a secure interface for the grate assembly.

Grates and clamp rings are available in:

- UV-stabilised ASA plastic

- 316 stainless steel

- Bronze

These options allow specifiers to tailor the drain system to suit the visual and environmental requirements of each project, from cost-sensitive builds to high-spec commercial or coastal developments.

The introduction of 88° outlet configurations to the VRTW and Sureflow ranges represents a significant enhancement to Allproof’s membrane-compatible drainage offerings. Designed with compact installations in mind, these new products deliver improved efficiency, reduced depth, and greater design flexibility for specifiers and installers alike. With a track record of innovation, local manufacturing, and commitment to quality, Allproof remains a leading choice for membrane roof and balcony drainage solutions in Australia and New Zealand.

Read More