Using NZ-Made to Elevate Design and Compliance at Commercial Bay

Since opening its doors Commercial Bay has been a key topic of interest in the A&D community earning it a position among the finalists for one of the industry’s most prestigious awards. With 300 metres of level threshold skirting the perimeter Warren and Mahoney along with Fletchers had to carefully select the correct supplier and product to cater for such a complex and varying application. NZBC E2 has set out strict criteria that level threshold drains must adhere to for performance and safety reasons. Due to the scale of commercial activity, foot traffic, plus the variety of joinery systems selected, the level threshold drain needed to be highly adaptable while maintaining the level of detail and aesthetic that Warren & Mahoney are renowned for.

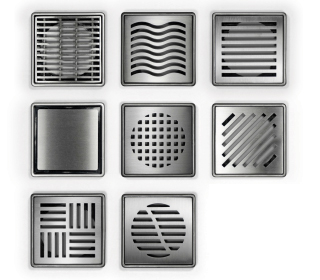

Allproof Industries’ Perimeter Drain was selected as the ideal solution. Allproof manufacture drainage and passive fire systems on the North Shore of Auckland and specialise in custom stainless steel systems. The Perimeter Drain uses a polymer concrete L shaped channel with a variety of off the shelf and custom grate options. This system allows for varying joinery dimensions that step in and out overhanging the channel by adjusting the grate width for a clean channel line around the perimeter of the building. On Commercial Bay certain areas at secondary entrances have wider spans of grate to accommodate for the building line, the system needed to be engineered for load rating on these areas to cater for traffic that is specific to these entrances. Allproofs Wedge Wire grate was selected for its customisable features, excellent hydraulic performance and R11 slip rating.

The transition between the Sky Lobby and the roof top terrace uses a revolving door, Allproof were asked to create a custom stainless steel drainage channel to the exact radius of the door allowing for level entry onto the terrace. Allproof’s Threaded Leg system with wedge wire grate was ideal for this. Allproof used the specifications from the door supplier to laser cut a stainless template to the required radius, this template was then tested on site to ensure the correct fit. Allproof’s fabrication team then used the template to hand fabricate the system rolling each element of the grate to the exact diminishing radius before welding the components together creating the full system.

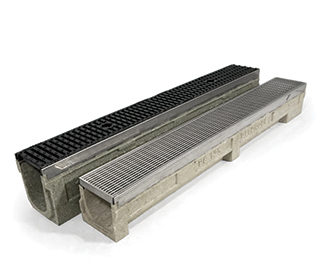

Allproof was also chosen for the drainage system running down the centre of the retail complex. The channel drain is installed as a podium set up with restricted depth due to the City Rail Link (CRL) line and station below the complex. A 75mm depth channel was therefore selected with the outlets directed into podium flanges below the surface. A heelproof cast iron grate for its durability, performance and aesthetics has been used, the characteristics of cast iron combined with high levels of foot traffic means that it will weather into the environment and blend with and enhance the laneway atmosphere the architecture creates.

By selecting a New Zealand manufacturer Commercial Bay significantly benefited from specialised knowledge in the NZ building code that Allproof were able to supply, along with a product range specifically designed for the local market and the ability to highly customise bespoke systems to the exact needs of the project.

Read More