Victoria & Vine: The ‘Channel’ to Success for a High-end Finish

Article produced for Plumbing Connection Summer 2022 issue.

A large new property development in inner-suburban Melbourne features individually measured shower drainage channels, removing many of the unsightly variations seen with standardised fittings, while still adhering to tight installation schedules.

Victoria & Vine is a New York-inspired development in Collingwood, Melbourne, designed by Cox Architecture and constructed by Hickory. The project consists of 241 apartments, including a $7 million penthouse with access to a health club, infinity pool, rooftop lounge, co-working space and business lounge. The development is a blend of nine individual buildings with a combined 200m street frontage, consisting of 11 retail spaces, including food and beverage offerings. This multi-tiered development uses a variety of materials, including reclaimed brick, glazing and pre-cast panels, to emulate New York’s Meatpacking District, referencing the iconic Collingwood Foy and Gibson warehouse.

As a premium development, product selections need to reflect the quality of the entire project. Ensuring the drainage requirements of all bathrooms within the 241 apartments are perfectly met on both an aesthetic and performance level requires attention due to the high-detail specifications within this project. Another important element that needed to be considered was the overall service and production schedule, as it needed to fit into this exceptionally tight construction timeline.

Each drainage installation is site-specific while providing the efficiencies of high-volume production.

Individual Attention

In all construction projects, there are minor variations. Rooms are rarely laid out within 0.5mm of the exact planned dimensions—doing so would be near impossible just to allow for the perfect fit of an off-the-shelf product, such as a shower channel. Even if this is achieved, the designer would have to detail the exact finished dimensions of the room at the detailing stage. Wall build-up of linings, membrane, tiles and adhesives would have to be determined perfectly to avoid a huge makeup of silicone, or requiring the tiler to squeeze in a channel that is made too large. This will ruin the aesthetic of the shower channel and the quality of the overall room finish.

The logical solution is to select a supplier that can fabricate the channels perfectly to suit the area in each individual shower. This provides the modern appeal of a wall-to-wall channel while navigating the challenges of making an off-the-shelf product fit.

Another consideration would be the location of the outlet. In large multi-level projects, there are often structural elements or other services preventing a channel from having a centre outlet. Selecting a custom channel allows for the outlet to be located at a point where a floor waste gully can be installed for ease of piping out, or to suit pre-installed passive fire protection. Products will often need to be made to measure on projects that prioritise a high-end finish.

Made to Measure

Cox Architects and Hickory are well-established companies with a wealth of high-end projects in their portfolios. Experience has given them a grounded perspective on how product and supplier selections can add value to project processes, with service and quality ranked highly. Hickory will review products and share information across their site managers, allowing for suppliers who provide excellent service to be used repeatedly throughout future projects.

This was a key factor in Cox Architecture and Hickory’s selection of Allproof Vision shower channels. Cox Architecture and Hickory have “been dealing with Allproof for a long time and it made sense to use them again, especially with the service we get,” said Yianni Psihogos, Project Coordinator at Hickory.

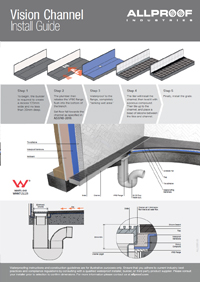

Allproof Vision shower channels are manufactured from high-grade stainless steel in off-the-shelf and custom sizes. The channel comes with a VF80 puddle flange which is designed to fit within a trench created in the subfloor. Waterproofing is dressed into the puddle flange as per AS 3740-2010 Figure 3.9, with the channel installed over the membrane; the channel’s outlet is directed into the drainage flange.

There are some key benefits to this method. The surface area of the membrane adhered to the flange is greatly reduced over a channel with an integrated flange. This method also allows for the puddle flange to be installed prior to waterproofing, allowing all other trades to complete their role without additional delays.

The tiler needs to leave a reveal of 80mm, plus allowance for silicone, where the channel is to be located. Once ready, measurements are to be taken for the channel length and outlet location and sent to Allproof. Upon delivery, it just needs dropping into place on a bed of levelling compound with a bead of silicone around the tiles and channel edge.

The tiled floor and channel will catch surface water, and the membrane will pick up any subsurface water that is able to track through the grout. The membrane then directs sub-surface water towards the outlet through falls outlined in AS 3740-2010 clause 3.4.

Should a channel with an integrated flange be selected, this would mean other trades could be held up by the production time of custom-length channels for each room, as waterproofing needs to be applied to the channel itself.

Rigorous Quality Control

Upon being selected, Allproof provided all required installation details along with product training and technical documentation. Almost 400 shower channels were supplied in phases. Once Hickory completed the tiling in a sequence of rooms, they took measurements and sent them to Allproof.

Allproof manufactured the channels to these measurements, thoroughly checked them through a rigorous QA process before clearly labelling each channel with its room number/reference and delivering them to site for installation.

Victoria & Vine opted for a wall-to-wall channel; however, the above benefits would also apply to stock channels, with the additional advantage of removing lead times and reducing site measures. A solution could be to pull the channel off the side walls, allowing for floor tiling either side (potentially 50mm). This means a channel can be ordered well in advance, as installers aren’t reliant on getting the final tile-to-tile measurement.

Additional economy can be found in utilising stock or standard sizes. Victoria & Vine had a specific aesthetic they were looking to achieve. One option to accomplish a modern shower design using a stock channel would be using the tile insert grate. This allows the channel to blend in with the surrounding floor tiles and becomes a very discreet drainage solution.

The benefit of selecting an established drainage supplier with standardised products over smaller custom fabrication shops is being able to draw on tried and tested solutions. A drainage manufacturer such as Allproof will hold stock in standard sizes and have the production techniques to ensure supply through busy periods of demand.

Additionally, drainage manufacturers understand the National Construction Code (NCC), AS/NZS Standards, installation methods and compatible systems. By selecting suppliers that specialise in specific products, installers can rest assured that the product they receive will be fully compliant, tested to all applicable standards, and suitable for use with robust warranties.