Lancaster Park Uses Recycled Plastic Drainage Channel

As a historic site of community value, the landscaping design needed to be considerate but also reflect a new, forward-looking city evolving from the 2011 earthquake.

Located in Christchurch, the Lancaster Park War Memorial Entrance Gate was built in 1924 to remember athletes who lost their lives during World War I. The gates are considered significantly important to the local community as a distinctive and memorable part that remained in place through the park’s evolution into one of the region’s largest stadiums.

Following the 2011 Christchurch earthquake, the stadium was demolished, transforming Lancaster Park into a recreational park with facilities for community sport, and it was reopened in June 2022. The Memorial Gates were mostly undamaged in the earthquake and were restored and opened to the public in 2023.

As a historic site of community value, the landscaping design needed to be considerate but also reflect a new, forward-looking city evolving from the 2011 earthquake.

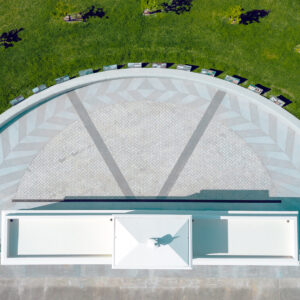

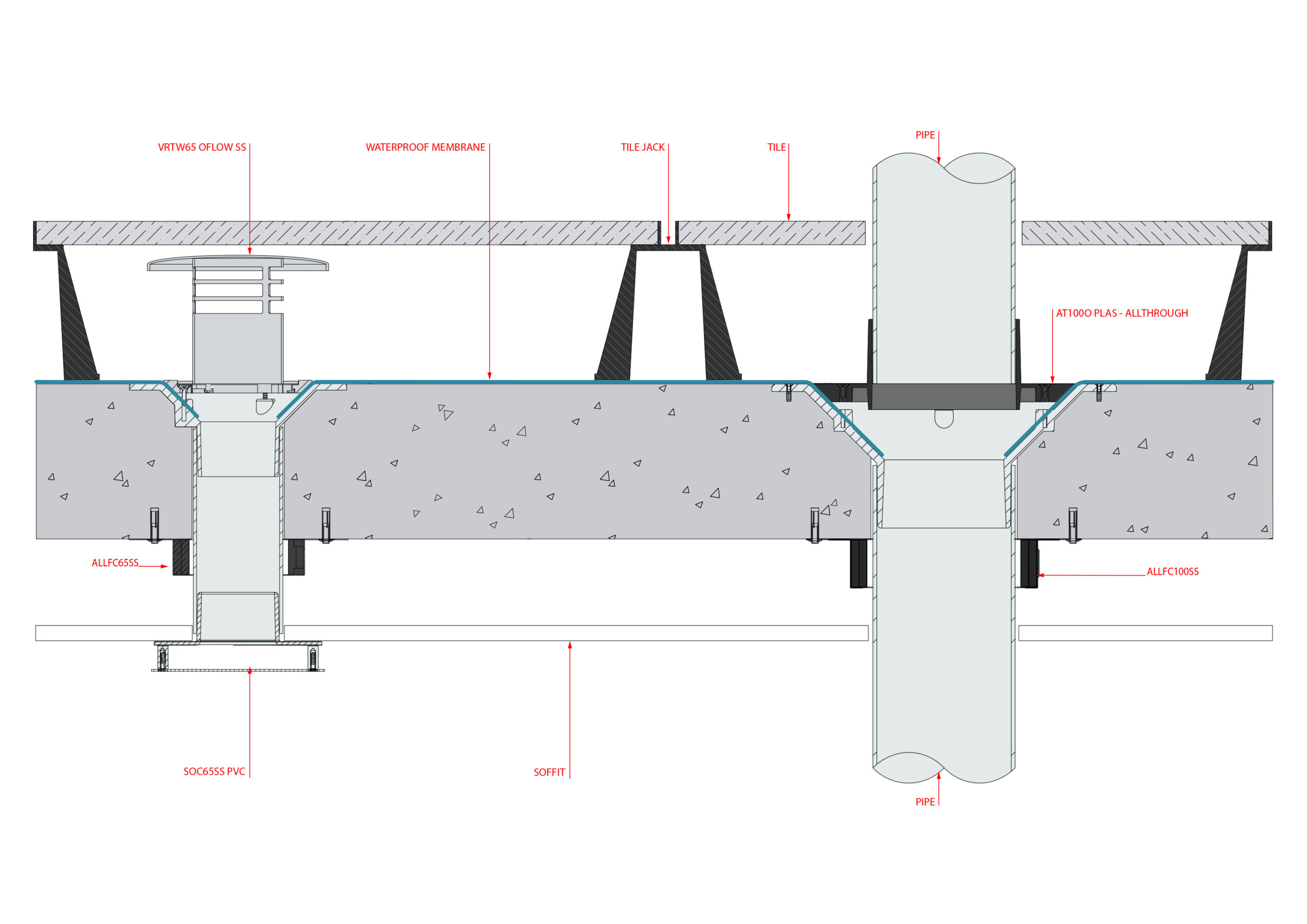

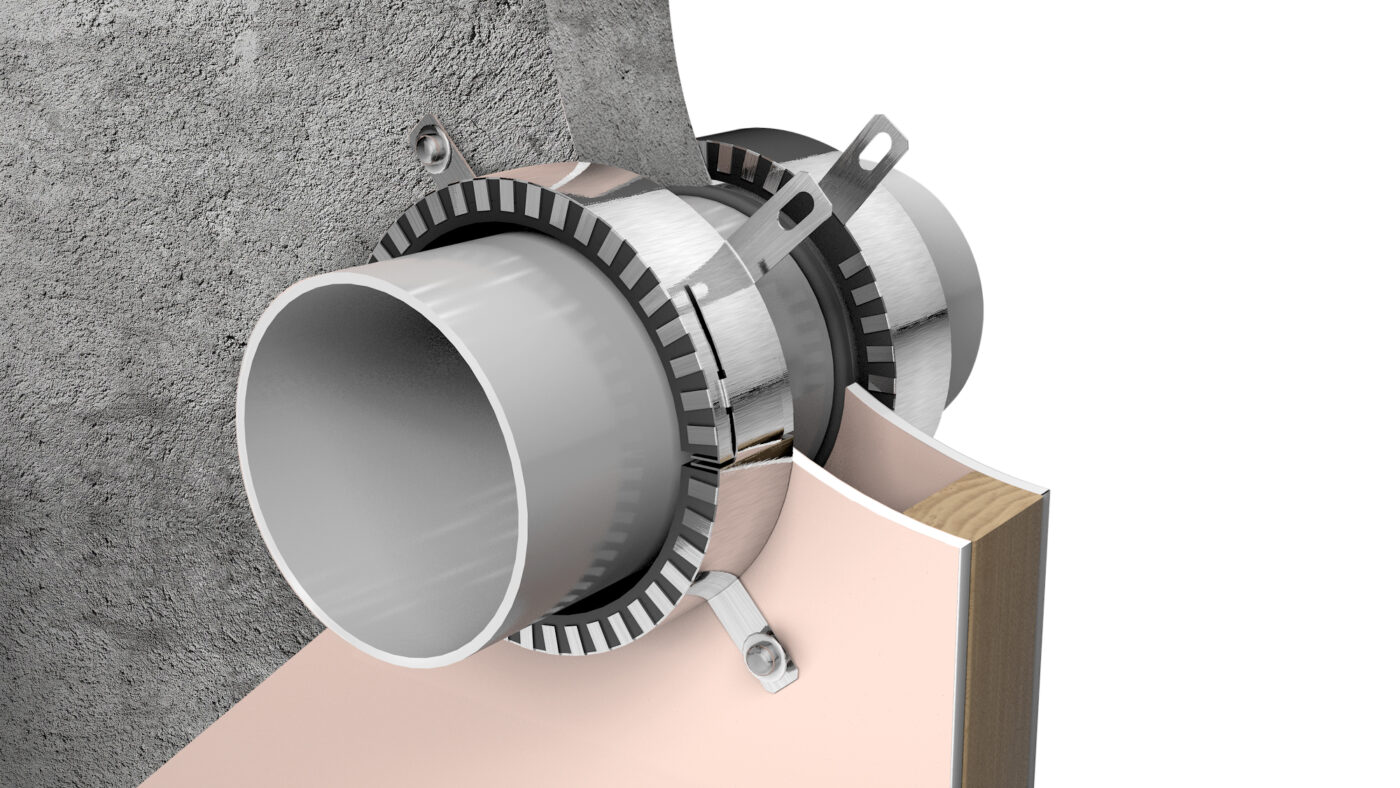

Allproof’s 200mm clear opening Commercial Channel drain was installed to capture and remove surface water from the Arc of History that was installed around the gates looking into the park.

The Heelproof Cast Iron (HCI) grate was selected, the material being sympathetic to the historical design of the Memorial Entrance Gate. The HCI grate features allow for large volumes of pedestrian traffic and provide a long service life as it is a highly durable solution with an impressive P5 slip resistance rating tested to AS4586.

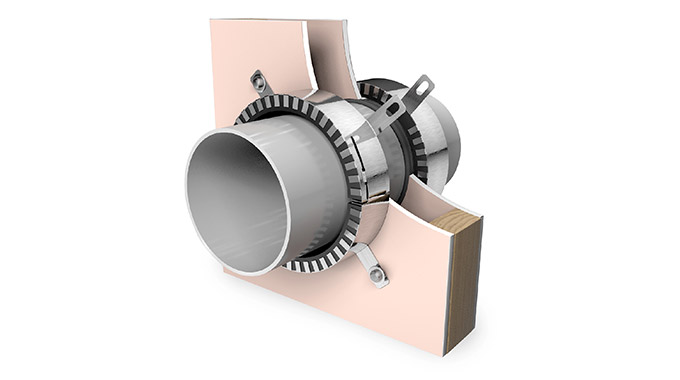

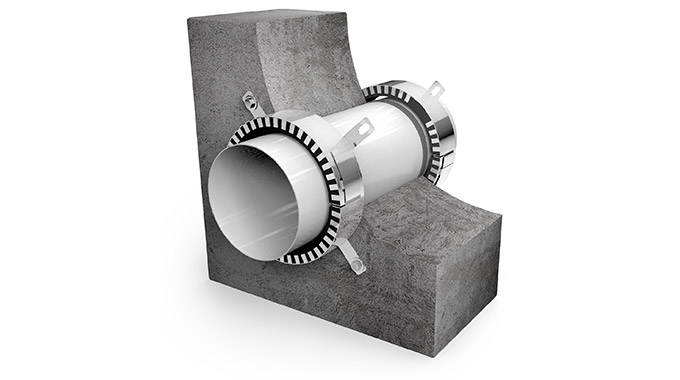

The channel is made from 100% recycled material, predominantly collected from single-use post-consumer streams. The recycled material provides a lightweight channel that improves installation by reducing installation time, breakages, costs, and embodied carbon through logistics, all without compromising on strength. The Commercial Channel has been designed to utilise the strength of the surrounding concrete to create a strong, durable solution.

The Commercial Channel was set off the foundations of the Memorial Entrance Gate; this avoided any disturbance to a historic structure while also allowing for a full concrete encasement and the ability to create a fall towards the channel. The channel works as a visual separation between an exposed concrete finished surface and pavers.

Allproof’s production facility generates its own clean energy on site from 450 solar panels. Toitū has acknowledged Allproof’s sustainability commitments at its manufacturing facility by awarding an Enviromark Bronze certification. This provides confidence that Allproof understands and values sustainable business practices while supporting projects across both New Zealand and Australia.

Read More